Pitting [1] c) Spalling: Spalling is one of the most destructive modes... | Download Scientific Diagram

Dynamical modeling and experimental validation for tooth pitting and spalling in spur gears - ScienceDirect

Applied Sciences | Free Full-Text | Dynamic Characteristics of a Gear System with Double-Teeth Spalling Fault and Its Fault Feature Analysis

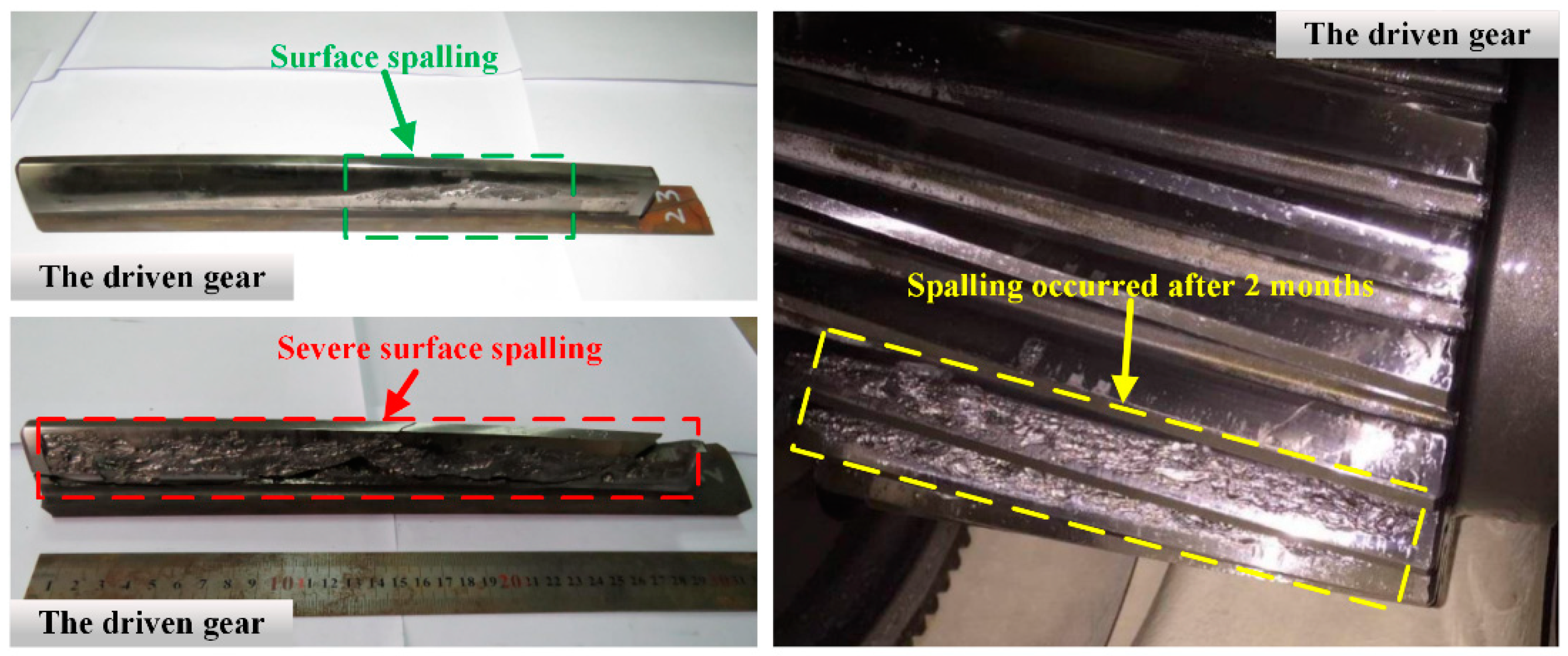

Materials | Free Full-Text | Fault Feature Analysis of Gear Tooth Spalling Based on Dynamic Simulation and Experiments

Typical gear TLFs: a) Chipped tooth. b) Spalling. c) Scuffing. d) Wear.... | Download Scientific Diagram

Materials | Free Full-Text | Fault Feature Analysis of Gear Tooth Spalling Based on Dynamic Simulation and Experiments

Photograph of the pitted gear teeth. Note, spalling and destructive... | Download Scientific Diagram